Design &

Manufacturing

Living Seawalls is driven by research and informed by nature. Our Living Seawalls modules are designed in collaboration with Reef Design Lab. The designs are based on complex structures found on rocky shorelines, for example rockpools, and crevices. Other designs are based on the structural complexity of biogenic structures, such as oysters and kelp holdfasts. The modular design of the habitat enhancing panels allows for a diverse range of microhabitats that encourages a wide variety of marine organisms to settle and grow. This increases available area for colonisation by marine organisms and provides refuge from environmental stressors and predators, increasing overall biodiversity.

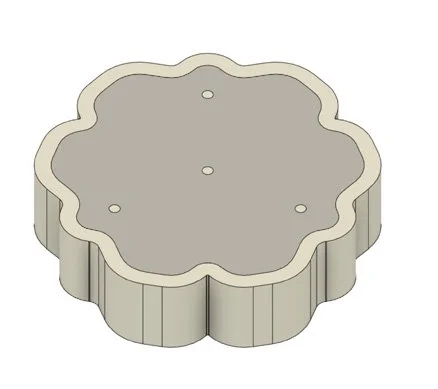

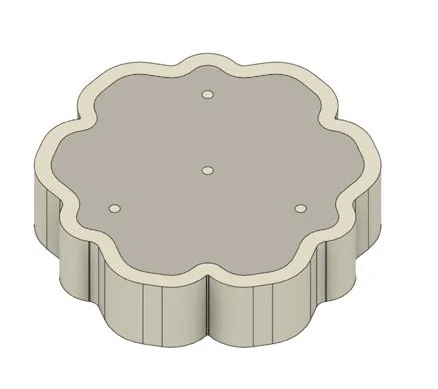

Our panels are first designed digitally by industrial designers at Reef Design Lab. Size and shape of the design features (e.g. rock pools and crevices) are informed by measurements taken from features on natural rocky shorelines.

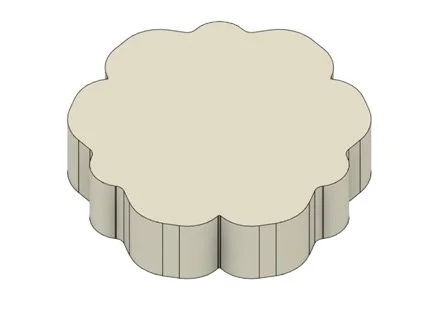

Once a panel design is finalised, a prototype is created using 3D printing technology. This method of printing allows us to recreate the fine details of the natural shorelines.

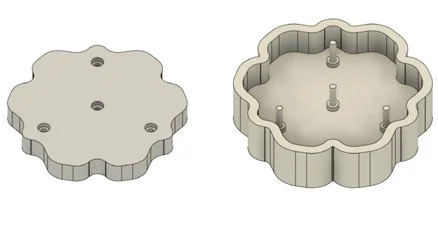

A reusable mould is then made from the 3D printed panel. From this mould, concrete panels can be cast and manufactured in large numbers.

Each panel design undergoes a series of tests to ensure they are able to withstand marine conditions.

Living Seawalls currently has 10 habitat panel designs, each targeting different features of natural shorelines which benefit diverse groups of marine organisms.

See our products page for more information about our range of designs, or contact us to see if Living Seawalls is suitable for your location.

How Panels are Cast

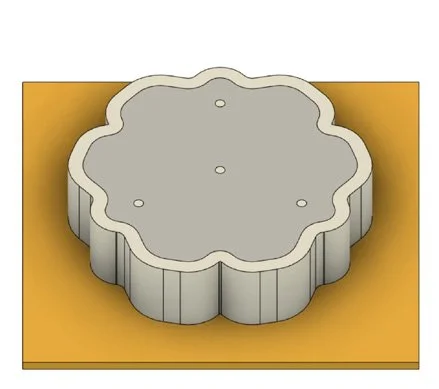

1. Assembly

Mateenbar is placed external to the bolt-hole silicone placeholders, to form an equilateral triangle. The PVC pipe is placed over the bolt-hole silicone placeholders.

4. Curing

The mould is removed from the vibrating bed and left to cure overnight.

2. Concrete Pour

Pour the concrete mix into the mould.

5. Demoulding

Flip the mould over and peel back the silicone to release the panel from the mould.

3. Vibrating

Panels should be placed on a vibrating bed to consolidation the concrete mixture.

Note: this process will require appropriate lifting equipment as the mould, filled with the concrete mix weighs 60 - 70kg.

6. Additional Curing

The panels will take 28 days to reach full strength. It is advised that installation occur after this period.